3D Scanning Success

The goal of any piece of automated machinery is to take a time consuming, manual process, and replace it with a fast, repeatable solution in order to allow operators to spend their time more effectively. In this case, operators were being asked to personally inspect and load hundreds of boards, one at a time, for subtle defects like twisting and bowing. It was a time-consuming, error-prone process.

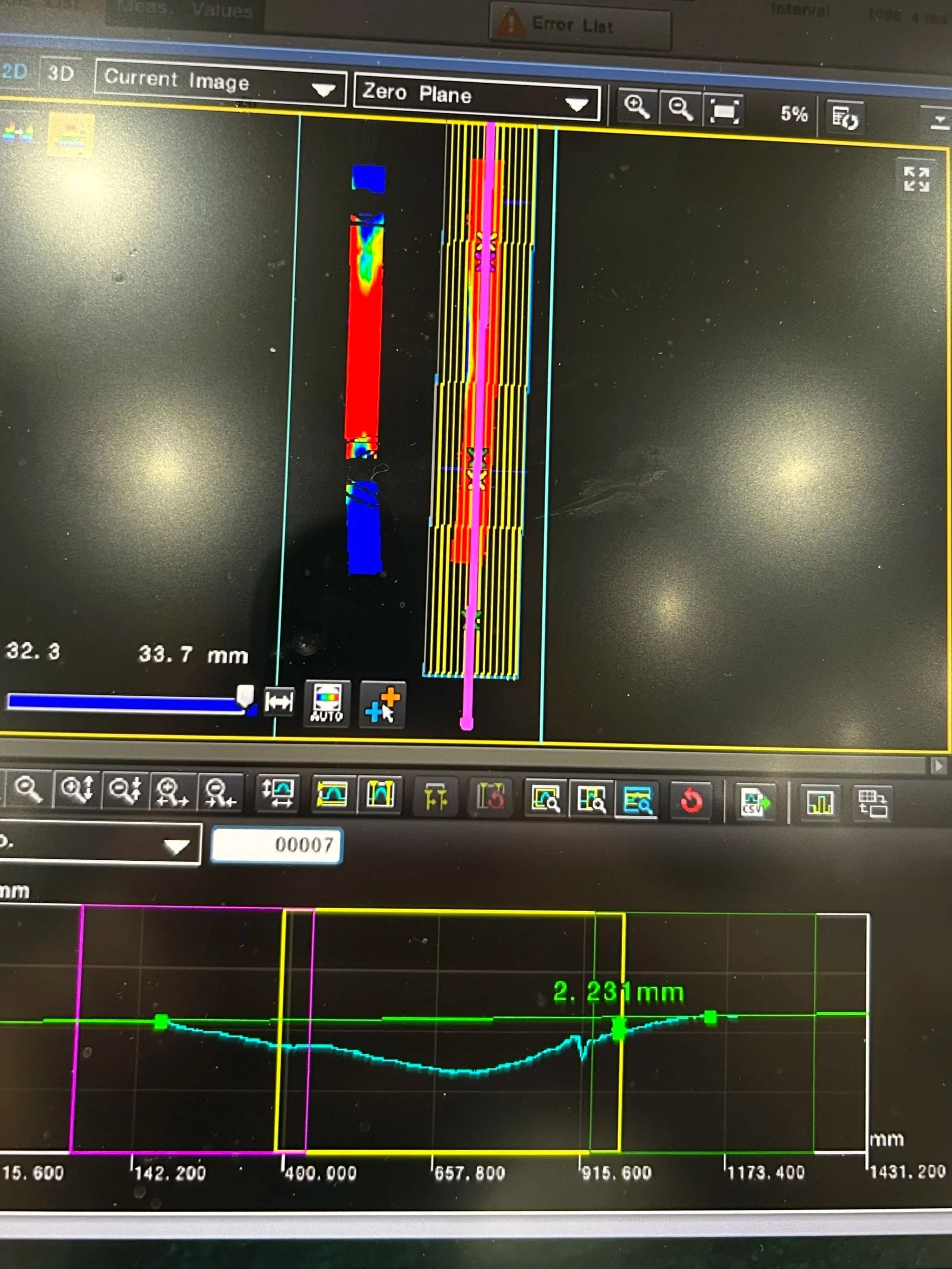

Earthbound was brought in to program the 3D vision system on this prototype build. The goal was to scan and load boards at a rate of one per second. We needed to detect common measurements and defects in wood boards such as length, width, thickness, bowing, twisting, cracking.

To accomplish this, we developed an application using Keyence LJ-X8000 lasers which scanned each board and detected these and other key measurements. Our goal was to develop a fast and reliable measurement system that could be trusted on a plant floor. The ultimate test was a GRR (Gage Repeatability & Reproducibility) study. We are proud to report that we passed this test achieving a GRR of less than 10% , which means that our system is not only accurate but also highly repeatable.

The biggest takeaway from this project was a high-level understanding of the Keyence 3D programming environment. This experience gave us the skills to develop a solution that turns raw scan data into a fast and reliable quality control system.